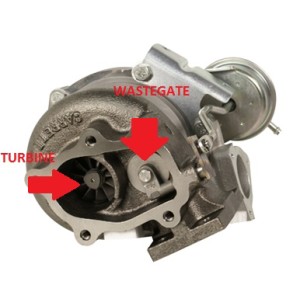

Let’s first go over how the wastegate and actuator work. The purpose of the wastegate is to maintain a particular boost pressure at the intake manifold by regulating the speed at which the turbo spins. It does this by regulating a pathway/door which diverts exhaust gases AROUND the turbine. The faster the turbine spins, the more boost the turbo generates.

The more exhaust you divert through the wastegate (the more you open the wasetgate door), the more you slow the turbo down and this is how you lower boost.

This wastegate is pushed open or held closed by the wastegate actuator and a number of other variables such as exhaust pressure. The actuator is a boost actuated diaphragm inside a canister with a rod sticking out as shown below. Boost pressure is applied to the canister and once the boost is higher than the spring pressure inside the canister, the wastegate actuator rod starts to move and open the wastegate.

The actuator doesn’t open the wastegate fully at a given single pressure. It starts to open it at a cracking pressure (also known as spring pressure) and then the more pressure you apply to the canister the more it opens the wastegate door. The amount of boost pressure this canister sees is regulated using the boost control solenoid which is controlled by the ECU and the tune running on the motor.

In spite of the ECU controlling boost pressure going to the actuator, the amount of boost a turbo can hold at any engine speed (RPM) is determined by a large number of factors. Some of these are the turbo itself, the engine displacement, the flow parts installed, the ambient temperature and more importantly for this discussion the spring inside the wastegate actuator and the preload on this spring. On OEM wastegate actuators we can’t change the spring inside the canister because they are sealed. On aftermarket actuators and external wastegates we can change the internal spring. Therefore, the only aspect that we can change on the OEM actuator is preload. Shortening the wastegate rod using the adjustment screws adds preload to the internal spring. The reverse removes preload. When you increase the preload you do two things. One is that you increase the boost pressure needed to start opening the wastegate. The second is that you lower the opening range of the wastegate door.

Increasing preload or changing the actuator with a higher spring pressure model (such as a Turbosmart pictured below) results in more boost! And that’s a good thing – right?

Well – the answer is a little more complicated.

First of all, keep in mind that making these kind of changes almost always requires that you get your tune adjusted. Reliable boost control is extremely important for the reliability of the engine. Secondly, you can introduce boost response issues such as boost spiking and boost creep. Most OEM turbos won’t suffer from these issues but it’s very important to make sure the boost of your vehicle reacts smoothly and is under control after you make any changes to the system.

Finally you have to make sure that more boost actually results in more power. When building and tuning a car, you have to look at the engine as a package. Changing boost will affect other variables such as fuel requirements, cooling requirements, and whether or not everything is still working efficiently.

A Turbosmart actuator on a Focus ST with the OEM K03 turbo will hold over 20psi to redline for example. The OEM actuator will only allow 13-15psi. In experimenting with this we found that holding more boost to redline makes the car quite knock prone even when using E85 mixes and mild timing. The turbo looked to be well out of its efficiency range and we kept dropping the boost until we were at 18psi at redline. Even then the motor was knock prone especially up top. Increasing the boost on the OE turbo in the upper RPM (past 6000RPM) is not worth the penalty in heat and timing reduction especially on pump gas.

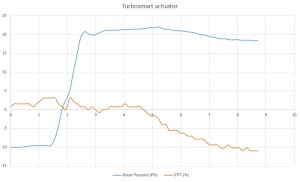

Another interesting bit of information was that without modifying the fuelling tables the short term fuel trims (STFT) became quite negative in the upper RPM (in orange in the graph below). The car calculates fueling based on boost pressure/manifold pressure and this drop in STFT indicated that for the boost measured the airflow was actually less than the ECU was calculating and expecting.

This is an other indication of the lack of efficiency of the K03 at those boost levels. The higher we pushed it in terms of boost, the more negative the trims.

other indication of the lack of efficiency of the K03 at those boost levels. The higher we pushed it in terms of boost, the more negative the trims.

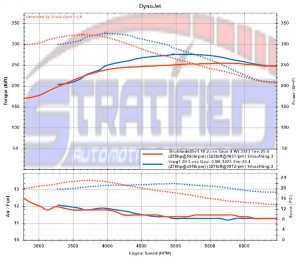

The Virtual Dyno plot below shows a similar story. This was on E85, stock actuator (red) vs Turbosmart (blue). There is a big difference in boost which results in a nice midrange increase in torque. However look at 6000 RPM – there the increase in boost makes no difference in power and we are probably driving the OEM turbo much too hard and reducing reliability. We had to reduce timing by around 6 degrees up top to keep the car from knocking even on 3.5 gallons of E85 mixed in the tank. Things got toasty and inefficient.

Conclusion on this? A little bit of extra boost is going to give you a nice bump in midrange torque. Adjusting the preload on the OEM actuator on the Focus ST carefully can give you a little bit more boost, but don’t overdo it. If you modify the boost control system and are not sure of what to look for make sure you have your tuner look over the data coming from the engine after the change. We offer the datalog report service for situations such as these.

Keep a very close eye on knock/timing corrections. This is especially true on pump gas as more boost (especially past 6000RPM) results in more knock. If you have poor pump fuel this may not be worth the penalty you will take in terms of timing and heat/inefficiency. Finally, driving the OEM turbo (or any turbo) to inefficient boost levels is likely to affects its long term reliability.