Upgrading the PCV system on turbocharged cars is common among the enthusiast community. This has historical roots with older vehicles that had sub-par PCV systems and looser piston sealing tolerances that NEEDED modification to vent effectively. Modern cars have much better designed systems that actually include catch cans (catch and release actually) right from the factory. More on this later.

First of all we have to know what we’re working with. This means delving into what the PCV system is and what it does. The PCV system serves 2 purposes:

1. It maintains a low crankcase pressure. Every piston engine will have some level of blowby which is caused by combustion gasses that move past the piston rings during the power stroke due to the high in-cylinder pressure. The looser the tolerances on the motor, the more of these gases will escape below the pistons. If you don’t vent them from the crankcase they can cause issues such as a decrease in power and will push oil out of the crankcase. This can mean dipsticks popping out, seals leaking oil, and turbos smoking from the oil drain being backed up and not draining. We often seen turbo seals misdiagnosed due to the poor crankcase ventilation.

2. Excessive crankcase pressure used to be vented directly to the atmosphere. However this does pollute and now it is being recirculated back into the intake tract. While this does bring some oil into the intake tract, pulling it back in HELPS in reducing crankcase pressure which is a good thing for performance.

On turbocharged cars you need to vent crankcase pressure under 2 distinct conditions: boost as well as under vacuum. This is why you will see 2 PCV pathways on modern turbo cars.

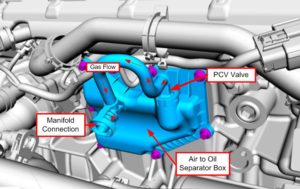

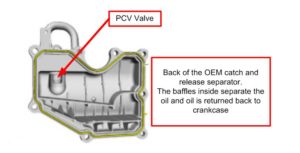

1.The vent under vacuum. The image below shows what it looks like on an Ecoboost or Mazda DISI engine but all manufacturers have a similar version of this idea. It is made of an air to oil separator (an OEM catch can), a valve that closes under boost, and a hose directly to the manifold. This side of the PCV system pulls crankcase pressure out when there is vacuum in the intake manifold such as at idle and during cruising. It separates the oil film and gases through the OEM separator, returns the oil to the crankcase and pulls the gases through the manifold. Under boost the PCV valve closes and prevents boost pressure from entering the crankcase so this side of the system does not flow at all under boost.

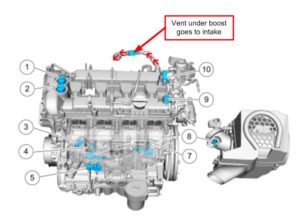

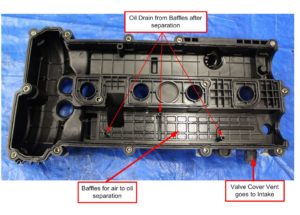

2. The vent under boost. When the PCV valve is closed and the car is under boost as well as to a lesser extent under vacuum when it works together with the first system, this is where crankcase pressure is pulled from. The intake before the turbo has a vacuum effect from the turbo pulling in air through the intake tube and gases are PULLED from the top of the valve cover. The valve cover itself acts as an air to oil separator (a second OEM catch can which is also baffled) and returns the separated oil to the crankcase where it belongs.

Now, let’s talk about improvements to these systems. Most people try to improve a few things:

1. The PCV system flow. If you have a motor that is pretty loose (a more race oriented built engine with forged internals) you will need to pull more crankcase gases because the engine does not seal as well especially when cold. Combine that with very high boost and you may need to vent more. The RS motor for example has larger PCV openings versus the ST motor in the Fords. In order to improve flow, you need to add more passages or enlarge air passages. However keep in mind that the OEM PCV system is well designed for the OEM motor. If you are getting a lot of blowby with the OEM motor, you probably need to address why there is so much blowby from the pistons rather than a better flowing PCV system. Also keep in mind that any obstruction you add to the PCV system (ie extra catch cans) can impede flow and therefore can cause issues such as higher oil consumption, leaking, and smoking turbos.

2. Keeping oil out of the manifold/engine. This is a big one for DI (direct injection) cars and turbo cars in general as oil coats the intake valves and can cause knock if a lot of it enters the air stream. This is the intent when installing ADDITIONAL oil to air separators such as catch cans. The additional catch can DOES help in the separation BUT the effectiveness is difficult to measure. It can look like they are doing a lot when emptied but the fluid pulled out is in large part condensation that is a normal occurrence as motors come up to temperature after a cold start. Below are some of our observations regarding installing additional air to oil separators on top of the OEM ones already there.

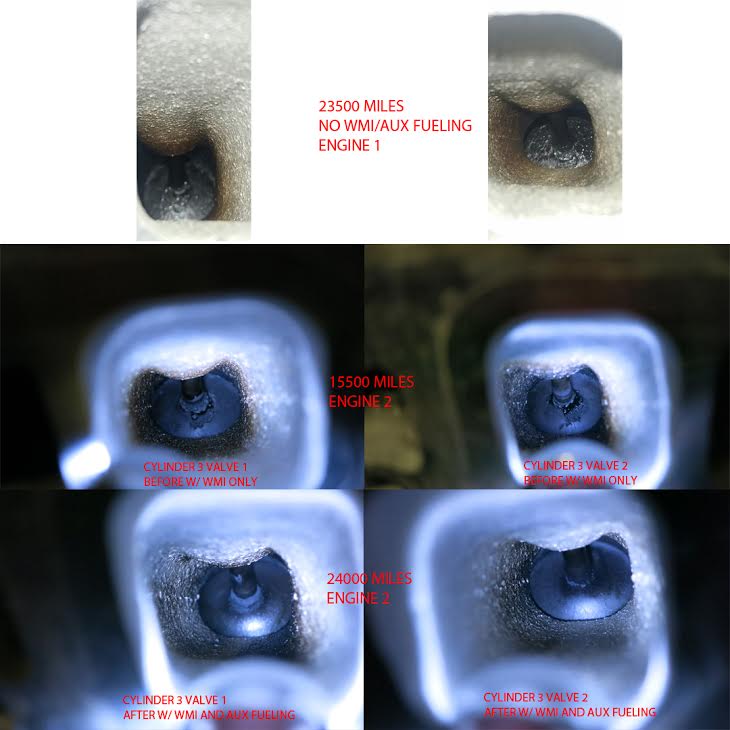

A. They do not stop carbon buildup on the back of valves in DI (direct injected cars). We have seen this time and time again and this is because some oil film still makes its way past the catch cans just like it does past the OEM catch cans. Further, flow reversion during engine operation still brings in oil over the valves. The most effective methods at preventing carbon buildup are: 1. Using high quality oils (some are being designed for DI operation specifically), 2. changing the oil often, 3. driving the cars hard to maintain high valve temperatures (yes having fun!) 4. and if possible running secondary injection across the intake valves which washes them clean and which more and more OEMs are starting to use.

B. They can cause PCV flow issues and should be monitored. If they overflow or freeze during the winter (which they do; remember the content of these is mostly water) they can block the system altogether. Similar issue if the fittings leak.

C. The most common location people install them is on the manifold to crankcase connection. This connection is not flowing any gases while the car is under boost. Remember there are 2 PCV systems.

D. They will not solve mechanical issues such as smoking turbos, excessive oil consumption, etc.; they can exacerbate these issues. Make sure you fully investigate the root causes of such issues.

The options to eliminate oil completely from the intake have their caveats. One is to vent the gases to the atmosphere which we don’t recommend. This is not as effective flow wise because there is no vacuum draw from the turbo or manifold and to top it off these gases smell and get pulled into the cabin air vents. Another option is to use the exhaust system to pull gases out using a venturi. This does require a good amount of customization to the exhaust system. Finally, you can have a separate pump to pull crankcase pressure out which is a bit extreme for a street driven vehicle.

Overall, it is important to understand that the flow of the OEM PCV system in a modern car is well matched to the OEM motor. Excessive crankcase pressure means something is mechanically wrong – either a blocked PCV system or excessive cylinder leakage that should be addressed. On a looser race built engine, increasing that flow means adding additional pathways for crankcase venting as well as different air to oil separators to match the new system. This means an overhaul of the OEM system altogether with bigger or multiple tubes and new separators/catch cans.

Hope this sheds some light on the the PCV system in your car. Happy Tuning!

The Stratified Team