I’ve seen a number of recent inquiries regarding the misfire count on Ford Ecoboost cars and I wanted to explain a little bit more about what it means, how the ECU determines when the car misfires, and when you should worry about it.

What are Misfire Counts?

First of all, the Misfire Count as a live parameter or datalogged represents the number of misfires detected by the ECU since the last engine start.

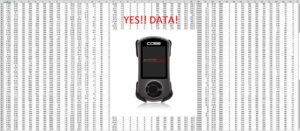

In the case shown above, the COBB Accessport monitor shows that there have been a total of 8 misfires since the engine has been running WITH THE COBB AP turned on.

What is a Misfire?

Combustion is a complex process. The power generated by an engine comes from the “power” stroke of the 4 stroke cycle. The power stroke is where the spark plug lights the air-fuel mixture inside the cylinder and you get a propagating flame front that evenly pushes the piston down. This is of course the ideal scenario. However sometimes, for a variety of reasons discussed below, the spark plug does not effectively ignite the mixture inside the cylinder. This causes what is known as a misfire. For that one cylinder, power is either low or not made at all during that one cycle and you will feel it as a short hiccup in what is otherwise smooth engine running and power delivery.

How is a Misfire Detected by the ECU?

Modern cars have a high resolution crank position sensor and multi toothed wheels. This is attached to the crank where the accessory pulley is and looks like this.

The ECU knows when the spark plug fires for each cylinder with respect to the position of the crank wheel and expects the engine to be accelerated during the power stroke. If the crank teeth are not accelerated during the power stroke (you can also feel this sitting in the car) it will determine that the particular cylinder has misfired.

Why does a Misfire Happen?

The engine needs a few elements for good combustion. These are air, the correct amount of fuel, effective mixing between the air and the fuel in the combustion chamber, a strong enough spark, and good compression.

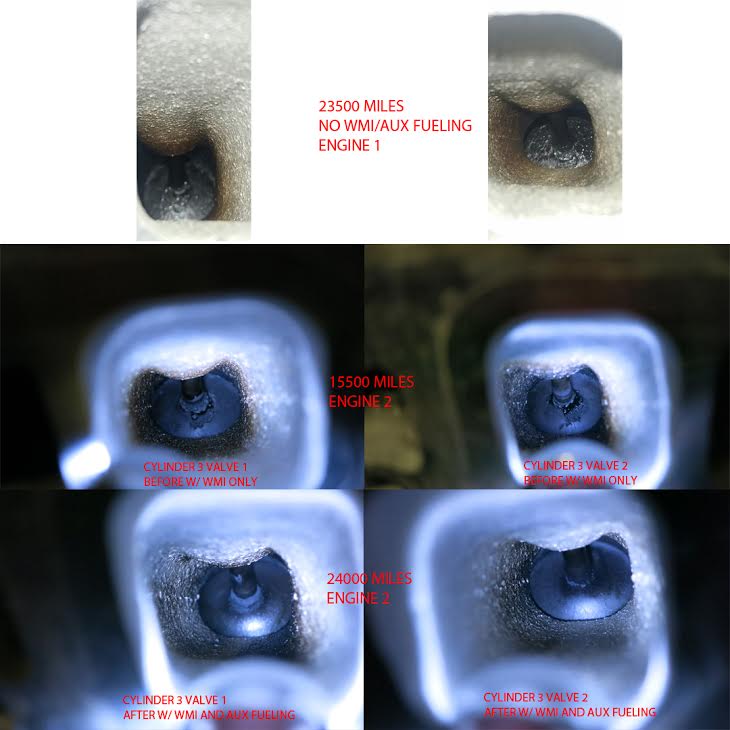

During NORMAL and HEALTHY engine operation misfires do happen but they are random and intermittent. For example, the Ecoboost engine tends to misfires at idle. This is because sometimes the air and fuel do not effectively mix and light off. This is a common issue with direct injection engines where the fuel and air are injected directly in the cylinder with poorer mixing characteristics. Engine designers and engineers get around this in multiple ways – sometimes with tumble flaps that increase air velocity (which the Ford does not have) – and through extensive internal combustion chamber and injection designs. These random idle misfires are undesirable for smooth running and emissions; however they do still happen even in healthy engines. The Misfire Count will pick these up and increment but a Check Engine Light (CEL) will not necessarily be triggered.

Another common reason for misfire is spark plug gap. This happens at high load under wide open throttle operation. A gap that is too large may prevent the plug from lighting when there is a dense mixture in the chamber under boost. We recommend a 0.026 inch spark plug gap to avoid these. You can feel these as small intermittent losses of power at wide open throttle but they are a simple fix.

Other failures of the ignition, injection, or air induction system can cause misfires (including carbon buildup) but the above two causes are the most common in healthy engines.

If there is internal damage to the engine such as a damaged ringland and associated loss of compression this can trigger a continuous misfire for that cylinder. The misfire count will increment much faster and eventually it will trigger a check engine light. This constant misfire is something you will FEEL and HEAR with the car at idle and it will be outside of the norm. A quick compression test will verify the internal health of the engine so there is no guesswork in this diagnosis.

When are the Misfires Codes (P0300, P030X for each cylinder) Triggered

The OEM ECU has a complex mechanism for determining when a misfire is part of normal operation, or when it means there is something that needs to be addressed. When it determines that something needs to be addressed; it will illuminate the Check Engine Light (CEL) and usually indicate which cylinder the issue occurred in (P0301 indicates cylinder 1, P0302 indicates cylinder 2, and so on).

There are two programs built into the ECU for determining two different types of failures. We will call these Type A and Type B.

Type A detects a failure that has recently happened or is sudden in nature (failed coil pack for example). This detects failures over a period of 200 revolutions. If the engine misfires in excess of 23% of the time (46 misfires per 200 engine revolutions) at low RPM or in excess of 5% at high RPM it will trigger the fault code under this condition.

Type B detects a condition that is progressing over time. This has a detection period of 1000 engine revolutions. For example in the Focus RS it triggers if 1.2% of revolutions result in misfires (12 misfires per 1000 engine revolutions). This is designed to catch progressing conditions such as worn spark plugs.

For the sake of simplicity, assume that your car is idling at 1000RPM. This means that for you to have enough misfires to indicate an out of tolerance condition, you will need to have at least 12 misfires during 1 minute of running at idle.

When should you worry and what should you do?

Because the ECU is keeping track of the misfires, you don’t need to! When a fault code is triggered for a misfire, this is when you want to investigate and look for an issue. Otherwise, keep spark plugs fresh and gapped correctly and keep in mind that misfires can and do happen on perfectly healthy engines!

The Stratified Team